Ningxia Xinhaoyuan Biotechnology Co., Ltd. was established in March 2012, located in Litong District, Wuzhong City. It is a national high-tech enterprise integrating the research, development, production, and sales of gelatin and collagen peptides, with a registered capital of 6905.6 million yuan and an area of 80000 square meters. The company joined the Institute of Physical and Chemical Technology of the Chinese Academy of Sciences to take the lead in realizing the industrial production of enzymatic bone gelatin technology in the global gelatin industry, subverting the century-old traditional gelatin production process. The technology has "six advantages". In 2014, the industrialization of enzymatic bone gelatin technology passed the appraisal of scientific and technological achievements of the Science and Technology Department of the Autonomous Region. The company has five scientific and technological achievements. More than 10 patents.

The company pays attention to scientific and technological innovation and has jointly established a gelatin technology research and development center with the Institute of Physical and Chemical Technology of the Chinese Academy of Sciences in the mode of "production, learning and research". At the same time, it has established cooperative relations with Ningxia University, Ningxia Medical University, Jiangnan University, and other institutions of higher learning, aiming at providing technical services for the world's gelatin and collagen peptide industries.

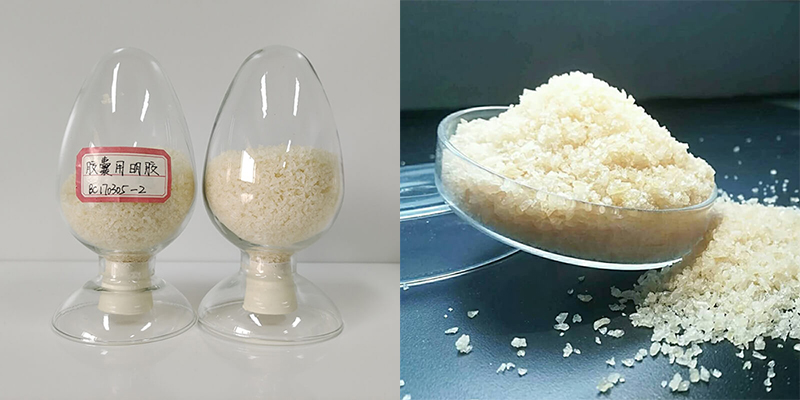

1. Special gelatin for optimizing the dissolution of capsule drugs. The disposable gelatin extraction developed by our company is to set the process parameters of gelatin extraction so that the gelatin with the set molecular weight and freezing power can be produced at one time. The capsules produced with this kind of gelatin are easier to dissolve and have better dissolution after being filled with powder. In the production of the gelatin, not only the molecular weight is small, but also the match of the freezing force is reasonable so that the strength of the capsule and the dissolution rate can be ensured in the production of the capsule.

2. Special gelatin to improve the toughness of the capsule. The gelatin we ed has high tensile strength, relatively balanced molecular size, reasonable matching of freezing force and viscosity index, and the capsule produced by such gelatin has a small difference in wall thickness and strong toughness, thus reducing or even eliminating breakage.

3. High-strength special gelatin for meat products. Our company can customize gelatine with a freezing strength range of 260-310Bloom G to meet different needs. Compared with other common gelatin, the added gelatin amount of the meat product achieves the same effect and can be reduced by 20 to 30%, and the method has a great contribution to the reduction of the cost on the premise of ensuring the quality.

4. Special gelatin for high-grade gelatin tablets and gelatin powder. Our company can customize special gelatin for high-grade gelatin tablets and gelatin powder, which can be used in pudding, cheese, cake, and other desserts so that the liquid can be quickly coagulated, the product has stronger coagulation, is easier to shape, and has the taste desired by consumers.

5. Special gelatin for temperature-resistant QQ sugar. The freezing temperature of QQ sugar special gelatin developed by us is 2 to 3 degrees Celsius higher than that of ordinary bone gelatin, which has strong adaptability in hot summer.

Quick-dissolving collagen peptide and production method and production system thereof

The invention adopts the procedures of raw material treatment, acid washing, gel extraction, filtration, concentration, instant sterilization, powder spraying and drying to produce the collagen peptide; in the acid washing process, the collagen peptide is stirred while being fed, A certain amount of prepare sedimentation agent is added to dissolve that collagen to form a coarse collagen solution, impurity in the coarse collagen solution and a hygroscopic component of the solution are removed by bag filtration and ion exchange column filtration, The combination of membrane concentration and evaporation concentration can greatly reduce the water content in the concentrated solution; In the invention, the collagen peptide is directly extracted from animal bones by an enzyme degradation technology, the advantages of a biological method are utilized, the whole production process has specificity and pertinence, the target product is easier to control, the biological activity of the target product is maintained, the composition structure and performance of the collagen peptide are stable, the variation is small, and the produced collagen peptide is beneficial to being directly absorbed by intestinal tracts.

微信公众号

手机访问